Optimize first mile delivery

- Home

- E-bike knowledge

- Optimize first mile delivery

The so-called “first mile” is the start of every supply chain – it begins where products are moved for the first time: in the warehouse, on the factory premises or during production.

In our blog post on the first mile, we showed you the challenges that the first mile entails. Now it’s time to get specific: how can you optimize your internal logistics – with a solution that is flexible, emission-free and economical?

What makes the first mile so crucial for the supply chain?

At this early stage, products are moved for the first time, often under great time pressure and in large quantities. Companies not only have to deliver on time, but also act sustainably and economically. What goes wrong here often runs like a red thread through the entire logistics process. It is therefore crucial to make this stage particularly efficient, safe and sustainable.

Cost pressure is high in many companies – especially when it comes to internal transportation. Vehicles such as delivery vans are expensive to maintain and often not even necessary for short distances. This is exactly where a cargo e-bike can be a simple and sensible alternative – especially for the first mile.

Challenges in first mile delivery & internal logistics

Short distances, high time pressure, limited space and ever new sustainability requirements – the first mile regularly presents companies with practical and organizational challenges.

We have already explained in detail here why this is the case and which typical problems occur in warehouse and plant logistics:

Optimizing transport processes: What cargo e-bikes can do in day-to-day operations

Craftsmen in particular benefit from using a cargo e-bike. The tools can be transported in an agile and targeted manner and the various loading areas and superstructures for XCYC Cargo E-Bikes also make it possible to transport finished workpieces effortlessly.

The use of a cargo e-bike can also make sense in internal logistics. And the operating costs remain low compared to motorized vehicles – this makes a noticeable difference, especially in daily use.

A cargo e-bike can be used spontaneously, without a special driver’s license, and gets materials from A to B quickly and safely.

How cargo e-bikes make first-mile delivery more efficient

Fortunately, there is no need to reinvent the wheel. There is already a solution that is becoming increasingly popular in practice: cargo e-bikes for commercial use.

Speed and flexibility in tight warehouse structures

Cargo e-bikes are compact, maneuverable and can maneuver in tight spaces where larger vehicles such as forklifts or vans reach their limits. This allows goods to be transported faster and more efficiently without blocking internal traffic.

Plenty of transport space – even for pallets

Thanks to their stable design and individually adaptable superstructures, they are ideal for transporting palletized goods. This makes them particularly interesting for companies where large quantities of goods need to be moved efficiently and in a space-saving manner on a daily basis – without noise, emissions or costly vehicle use.

Sustainability and emissions reduction

While vehicles powered by fossil fuels cause high emissions, cargo e-bikes are a great environmentally friendly alternative. They are emission-free, lower CO₂ emissions and reduce noise pollution – particularly beneficial in enclosed warehouses.

Flexible use – even without a driver’s license

E-cargo bikes offer a simple solution here. They can usually be used without a driver’s license, are easy to operate and can be used flexibly by the entire team – without any major training requirements.

Practical examples - How companies successfully use XCYC Cargo e-bikes

Depending on the industry and company structure, the first mile can look very different – sometimes it’s about short distances in the warehouse, sometimes about supplying branch offices or production lines. XCYC Cargo e-bikes offer a flexible solution that can be adapted to different requirements. The following examples give an insight into how versatile they are already being used in practice.

Logistics companies – transportation between storage and production areas

In large plants or on extensive sites, goods, components or parcels are moved between the warehouse, production and dispatch every day. The XCYC e-bike offers a fast and flexible solution, especially when there are frequent short distances to and fro.

Wholesale markets & distribution centers – handover and forwarding of deliveries

Goods from incoming goods are sorted and prepared for further distribution. XCYC bikes help to manage these internal routes quickly and smoothly – even between halls or in traffic-calmed zones.

Recycling & waste management – collection of recyclable materials at the company or in the city

Whether paper, cardboard or scrap metal: smaller collection points can be efficiently approached and emptied with an XCYC Cargo e-bike – especially in parks, courtyards or on confined company premises.

Craft businesses & small manufacturers – Between warehouse, workshop and store

The XCYC cargo bike is a reliable solution for moving materials or finished items between locations on a daily basis. No parking problems, no driver’s license required – just load up and go.

Small producers & manufacturers – delivery to local dealers or intermediate warehouses

Soaps, candles, textiles or delicatessen products are delivered directly to small stores or distribution points. XCYC e-bikes offer enough space, flexibility and comfort for this – and can even be parked directly in front of the store.

Flower & plant companies – delivery from the greenhouse to the point of sale

Fresh plants or bouquets need to be transported quickly and carefully. With the right body, XCYC bikes are ideal for transporting goods to wholesalers, weekly markets or flower stores – without CO₂ emissions.

Agriculture – transporting fresh produce to the collection point or market

Whether vegetables, fruit or herbs: on smaller farms, produce is often transported from the field to the farm or collection point several times a day. With the XCYC Cargo e-bike, this can be done without a tractor, without noise and without wasting time.

Profitability analysis - Why investing in cargo e-bikes pays off

Whether it’s the purchase, energy consumption, maintenance or insurance – there are big differences in running costs between cargo e-bikes and classic vans. Daily use over short distances in particular shows how much can be saved in the long term with the right solution.

Wer genauer hinschauen will, findet hier einen umfassenden Kostenvergleich mit konkreten Zahlen, TCO-Rechnung über fünf Jahre und einer Einschätzung zur Lebensdauer verschiedener Fahrzeugtypen:

FAQ – Häufige Fragen zu Cargo E-Bikes in der ersten Meile Lieferung

Are you considering whether a cargo e-bike is right for your company? Here you will find answers to typical questions about its use in internal logistics and on the first mile.

More general information on technology, equipment and accessories can be found here:

Cargo e-bikes have significantly lower running costs than conventional transport vehicles – both in terms of energy consumption and maintenance and insurance.

Operating costs – Energy:

Fully charging a 500 Wh battery costs around €0.30 or approx. CHF 0.28 (depending on the electricity tariff). This allows you to cover around 65 km. A battery lasts an average of 15,000 km before it needs to be replaced.

Maintenance costs:

An inspection twice a year is recommended to ensure smooth operation. The costs start at around 40 € or approx. 38 CHF per service. A shorter maintenance interval may be advisable for high loads or daily operation.

For comparison – vans (e.g. Ford Transit):

-

Insurance + road tax: approx. 215 € / 205 CHF per month

-

Maintenance & operating costs: approx. 430 € / 410 CHF per month at 15,000 km mileage

-

Other costs such as inspections, fuel and parking fees are added to this.

Conclusion:

In direct comparison, the running costs for cargo e-bikes are significantly lower – both in euros and in Swiss francs. Anyone who regularly travels short distances not only saves CO₂, but also money.

To ensure that your XCYC Cargo e-bike remains reliable in everyday use, regular maintenance is advisable. Depending on use, we recommend the following intervals:

-

Lubricate chain: every 200-500 km

-

Clean & grease rear axle: every 2 weeks

-

Clean & lubricate the stanchions of the suspension fork: every 2 weeks

-

Grease the suspension fork thoroughly: every 600 km or once a year

-

Grease steering damper & ball pillow block bearing: every 600-1,000 km or once a year

-

Seatpost maintenance: every 600 km or once a year

-

General inspection (brakes, battery, tires, etc.): 2x per year

If your XCYC e-bike needs a repair, please contact the specialist dealer from whom you purchased it first. Have your proof of purchase ready and check whether the repair is covered by the warranty.

If the retailer is no longer available or you have any questions, you can of course contact us directly – we will be happy to help you.

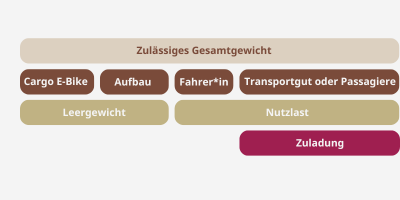

The maximum payload of an XCYC Cargo e-bike depends on the model and the country of use – because the legal requirements in Switzerland are different to those in Germany or the EU.

Important: The payload is the weight of the transported goods including the body, but excluding the rider’s weight and the bike itself.

This is how you calculate the maximum payload:

Payload = permissible total weight – tare weight of the bike – rider weight – body weight, if applicable

Sample calculation (XCYC Work 4.0, use in Germany):

Permissible gross vehicle weight (GVW): 300 kg

Weight of the bike (without body): 100 kg

Rider weight: 80 kg

➡️ Maximum payload: 300 – 100 – 80 = 120 kg

If a body weighs 20 kg, for example, there is still 100 kg of real payload for transported goods.

Our XCYC cargo bikes at a glance: Maximum authorised weight

| Weight (without superstructure) | Maximum authorised total weight DE & EU | Maximum authorised total weight CH | ||

|

XCYC Work Models |

100 kg | 300 kg | 200 kg | |

|

XCYC Allround Models |

58 kg | 250 kg | 200 kg |

XCYC Cargo e-bikes are equipped with reliable hydraulic disc brakes that ensure safe braking behavior even when heavily loaded and in continuous use. Different systems are used depending on the model:

XCYC Work 4.0 / 4.0 Eco / 4.0 T

Front wheel brake:

- Work 4.0 & 4.0 Eco: Shimano T6000, Ø 203 mm

- Work 4.0 T: Tektro HD-T-740, Ø 203 mm

Hinterradbremse (2x):

- Work 4.0 & 4.0 Eco: Shimano T6000, Ø 180 mm

- Work 4.0 T: Tektro HD-T-745, Ø 180 mm

XCYC Allround 4.0 / 4.0 Eco

Front wheel brake:

- Shimano T6000, Ø 203 mm

Rear wheel brake (2x):

- Shimano T6000, Ø 180 mm

Additional safety equipment (all models):

- Parking brake for stable parking when loading and unloading

- Electric pushing aid for easy maneuvering when fully loaded

- Lighting in accordance with StVZO for safe use in road traffic

The amortization period of a cargo e-bike depends on several factors, including

- Acquisition costs: A high-quality cargo e-bike costs between CHF 8,000 and CHF 15,000 or more.

- Savings compared to a car: If it serves as a car replacement, you save on fuel, insurance, maintenance and parking fees.

- Area of application: If it is used commercially (e.g. delivery service, craft business), it can be profitable more quickly.

- Tax advantages & subsidies: Depending on the country or region, there are subsidies or tax write-offs.

A rough estimate:

- Private use: 3-6 years if it partially replaces a car.

- Commercial use: 1-3 years if it is regularly integrated into the business.

For a more precise calculation, individual costs and savings would have to be taken into account.

Conclusion: Future-proof working with cargo e-bikes

Cargo e-bikes are a practical alternative for in-house transportation. They also get around well in tight spaces and, thanks to flexible superstructures, can move anything from small parcels to pallets – without any emissions.

The lower purchase and operating costs make the switch economically attractive in many cases. At the same time, they require little effort to handle and promote a healthy way of working through physical activity. With cargo e-bikes, you are well prepared for the challenges of the future.

Switching to a cargo e-bike can quickly pay for itself: Lower purchase and maintenance costs usually lead to amortization within 1 to 3 years.

Ready for change?